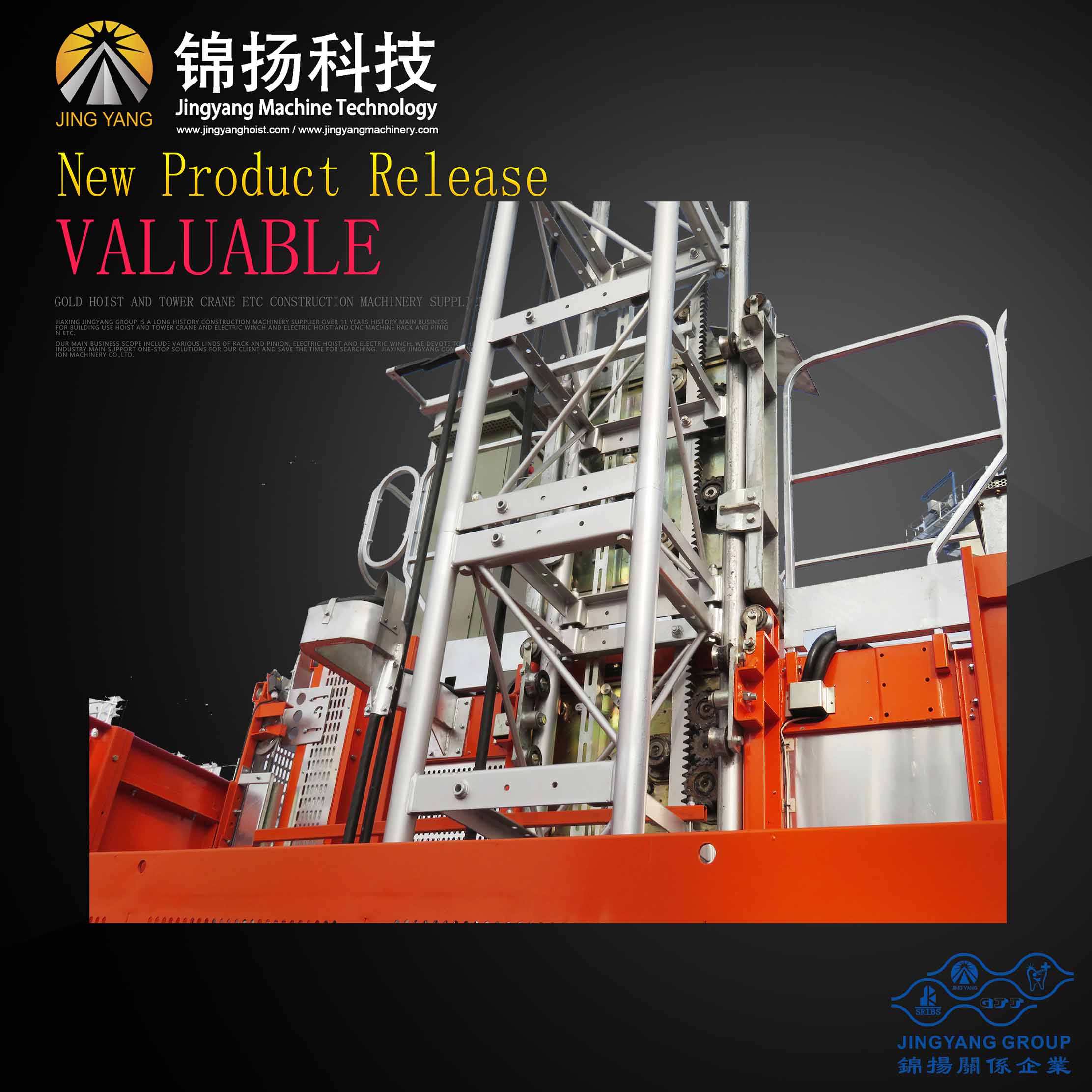

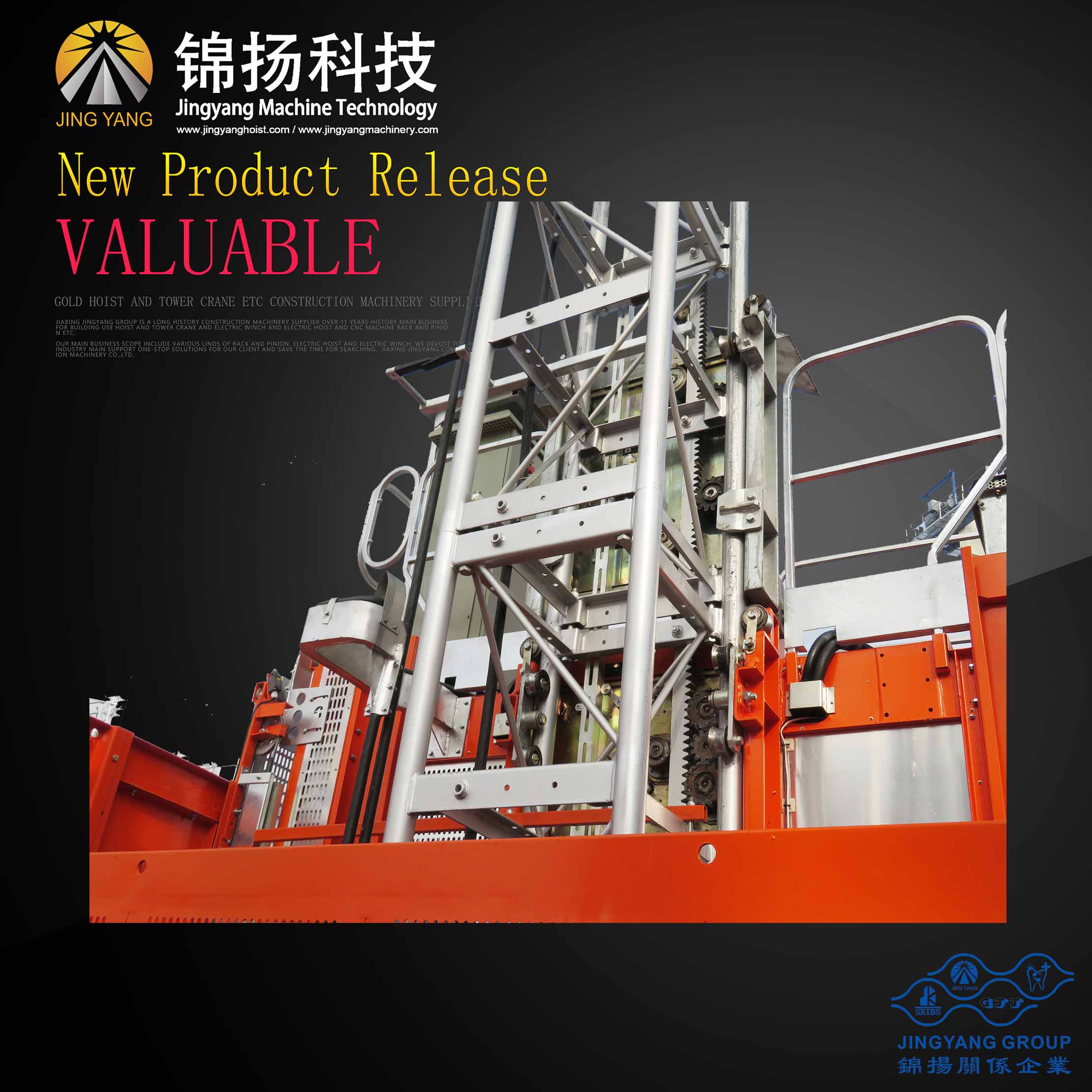

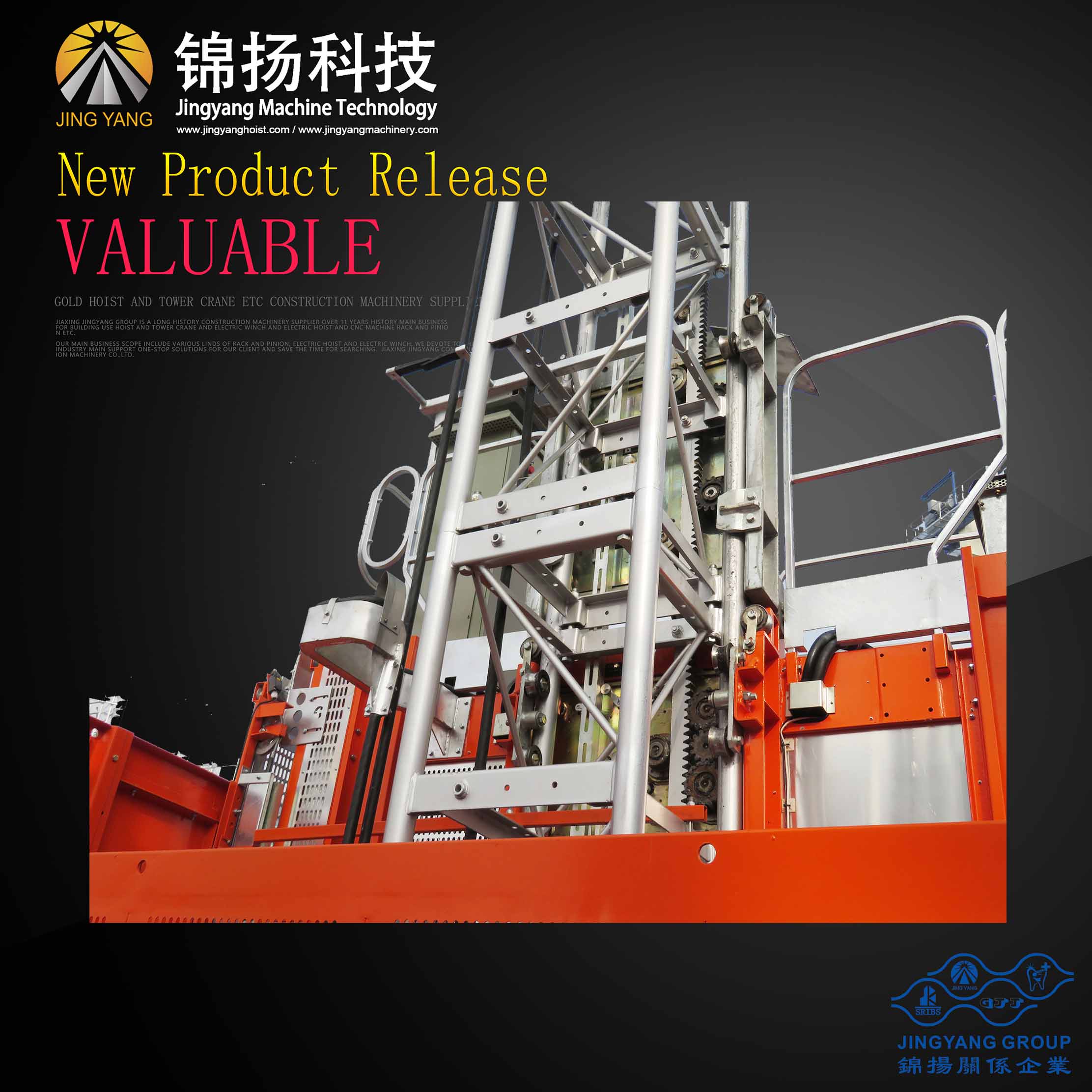

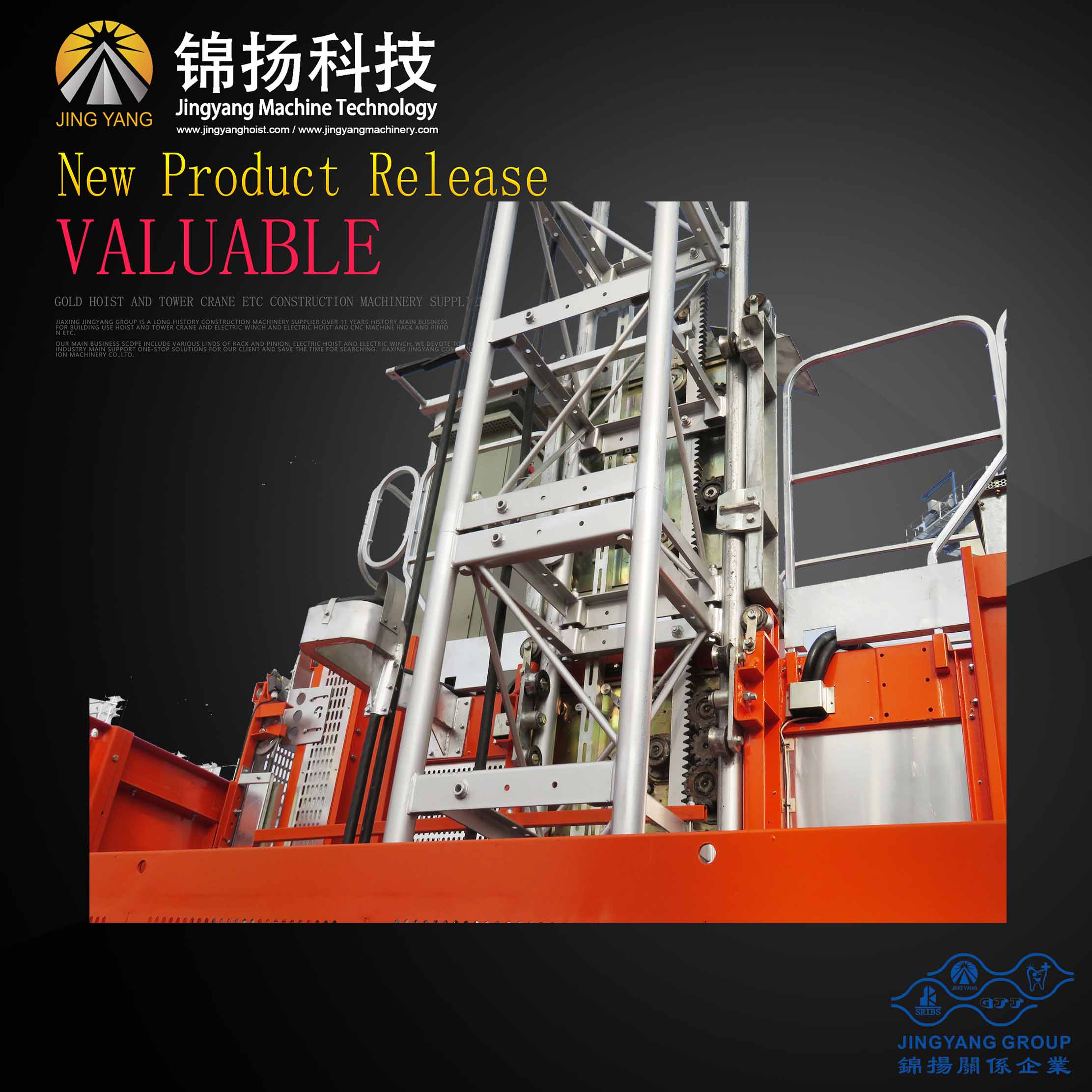

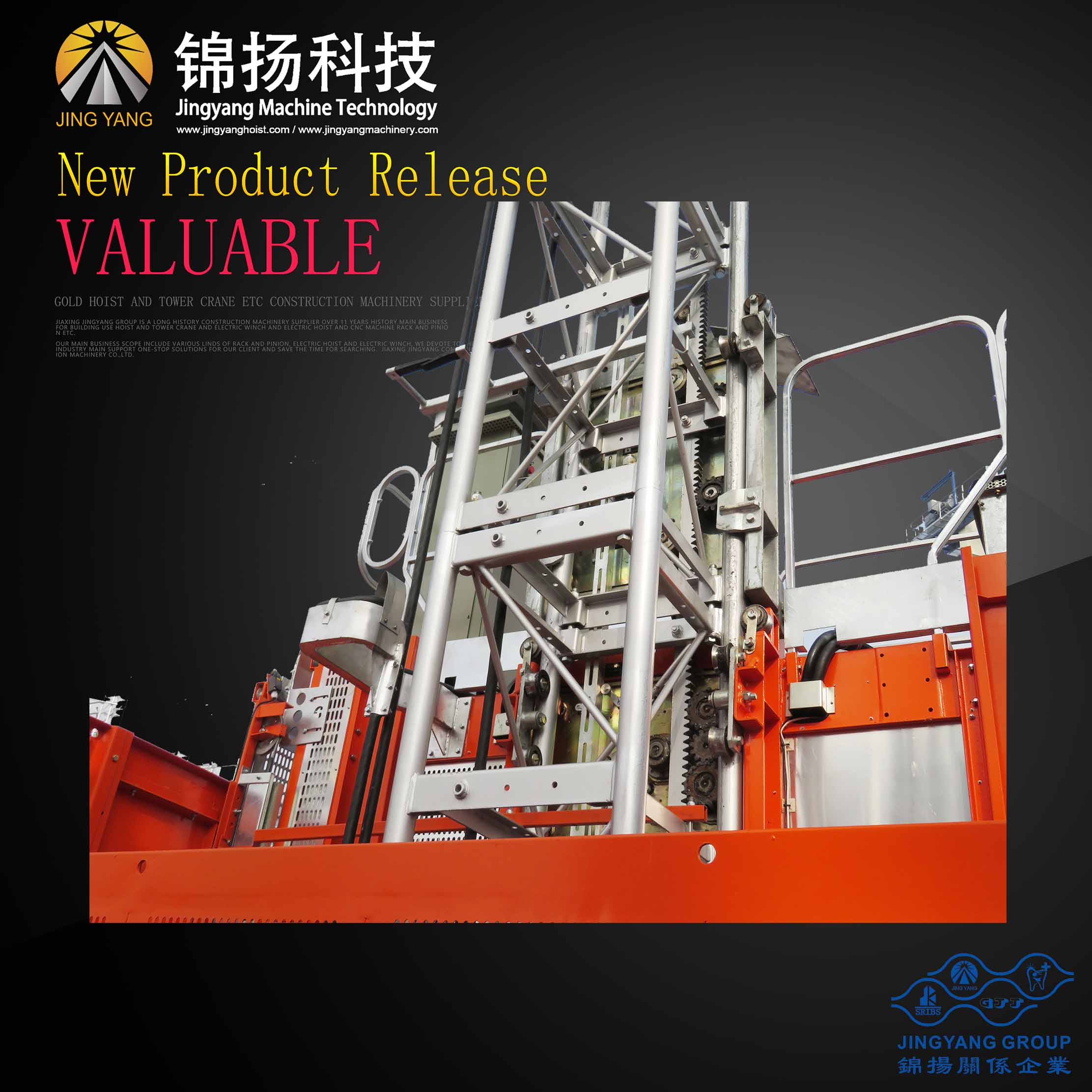

Manufacturer of Nylon Ball Bearing Wheel - GJJ passenger hoist part SC200/200 Construction hoist reducer 1:16 ratio speed – Jinyang Detail:

We will provide you with high quality products and excellent service.

Construction Hoist Gearbox

Construction Hoist Gear reducer

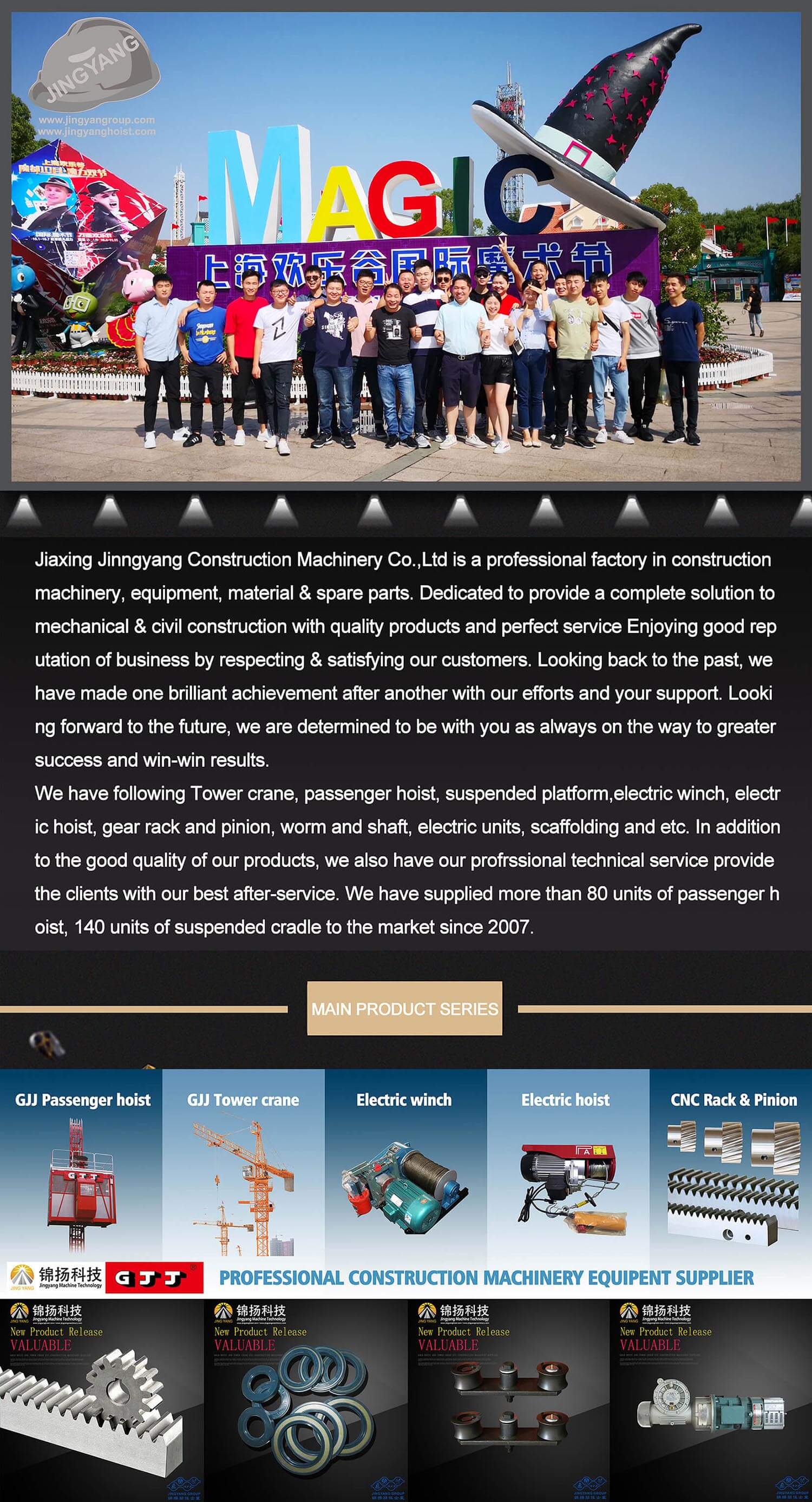

1. Center to center distance 125mm

2. Ratio: 10, 12, 14, 16, 25

3. Operating duration 25%

Construction Hoist Gear reducer

Construction Hoist Gearbox

1. General Status:

Comparing with general worm transmission, Arccolumn worm transmission’s contact linc benefits to dynamic pressure oil mcmbranc’ s generation. During operation, lower oil temperature, stonger anti-aggludination capacity, stablc work, less shake, lower norse, higher transmission efficiency, excellent proccss technology. Arecolumn worm. Transmission is high technology product for widely application which is assigned by State. Arccolumn. Worm speed reducer is substitute designated by Mechanical Bureau. It has got Gb914788series worm red ucer standard. This worm speed reducer could be applied for reduced speed transmission for all different industrics, like: metallurgy. Mine, lifting, chemicals, light industry, construction ctc. It is substitute of the general speed redueers used for above in dustrics. The suitable work temperature is among40℃till+40℃ input speed is less than 1,500 rpm, worm could turn in forward and backward dircctions.

2. Installation, operation and maintenance of secd reducer:

a) Speed reducer should be installed on a stable place where it’s convenient to fill or drain oil and good air circulation;

b) The original driver and working machine of speed reducer must be centralized, and the tolerance can’t exceed acceptable data of coupler.

c) After installation the speed reducer could work flexible when turning by hand, no block.

3. This speed reducer’s oil volume as following sheet for reference.

| Distance betwcen two shafts(mm) | 80 | 100 | 125 | 144 | 160 | 200 |

| Oil volumc(L) | 1.6 | 2.7 | 4.7 | 6.7 | 8.8 | 16 |

4. Category

| Distance between |

Two shafts(mm)125(144)Speed

ratioNominal8.25101214162025Actual8.2510.33(10)1214162024.5

| Number | Weight | Transmission Ratio | Center Distance |

(mm)Output power

(KW)Ordering instruction 150Kg1:1612511.6Please specify

transmissionratio and type

when ordering 21:1812510.3 3 1:1412511.72

B.Installation

The base-plate must be plane and stoutness and the base-plate must be screwed down and shock proof.

The connecting shaft of prime mover, reducer and operation device must be coaxial installation.

The diameter tolerance zone of input and output shaft is H6, the holes of fittings( such as couplings, belt-pully, sprocket wheel and so on) must properly mate the shaft, which prevents bearing from breakage because of over-loose mate.

Drivers such as sprocker wheel and gear must be fitted close to bearings in order to reduce bending stress of hanging shaft.

While assembling motor of WPD reducer, it is necessary that proper amount of butter applies to the warm shaft input hole and keyway, avoiding assembling too tightly and rusting after using for a long time.

When ordering or using all kinds of WPD type, if the motor weight is bigger than the common,supporting set is required.

| Speed ratio |

(I)Center Distance

(mm)Input Speed

(r/min)Input Power

(Kw)Rated output Torque

(N.M)TransmissionEfficiency

(%)14125150011.211288910009.919127687.416125150011.0611368810009.651141787.520144150013194286.5100011.52251285.425125150013216684100011.4265083

C.Usage

Before using,please check carefully whether the reducer modle, distance, ratio, input connecting method , output shaft structure, input and output shaft direction and revolving direction accord with required.

According to the requirement of selecting lubricant oil in the product manual. Please fill proper category and brand lubricant.And then screw on the vent-plug, unlock the small cone-plug of vent-plug.Only after doing these, reducer is already for startinh up running.The proper brand and adequate lubricant oil is required, replacing oil in time conforming to the request of product manual is also necessary, especially after using first 100hours, it is required refilling new oil.

When abnormal circumstances occur, please stop and check reducer per solutions and reasons for faults of reducer(allowable highest oil temperature is 95, under this temperature limit, if oil temperature no more goes up, please let reducer continue running).

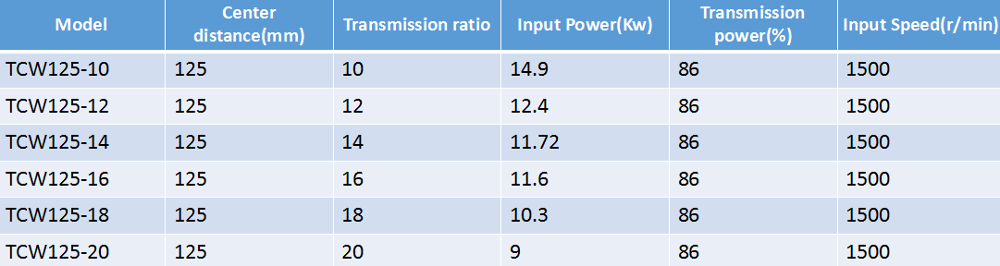

Product detail pictures:

Related Product Guide:

Crane Technology Will Slash Mineshaft Pre-Sink Time | Saj30 For Construction Lifter

Speed Reducers Market Report 2018: Segmentation by Product (Gear reducer, Worm wheel reducer, Planetary gears, Cycloid reducer, Harmonic drive, Others) by Application (Industrial industry, Food industry, Mining industry, Construction industry, Others) | Saj30 For Construction Lifter

Our focus on should be to consolidate and enhance the quality and repair of present products, in the meantime constantly establish new products to meet unique customers' requires for Manufacturer of Nylon Ball Bearing Wheel - GJJ passenger hoist part SC200/200 Construction hoist reducer 1:16 ratio speed – Jinyang, The product will supply to all over the world, such as: UAE , Seattle , Swiss , We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

We guaranee our product all origional GJJ high quality item, no fake item supply.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.

-

Factory making Hanging Glass Sliding Door Pulle...

-

Best-Selling Hoist Crane Remote Control - GJJ ...

-

New Fashion Design for G24yb50 Excavator Spare ...

-

New Delivery for Brake Pads Brake Block - GJJ ...

-

High definition Spare Parts Zoomlion Crane - M...

-

Chinese wholesale Stainless Steel Thread Shaft ...