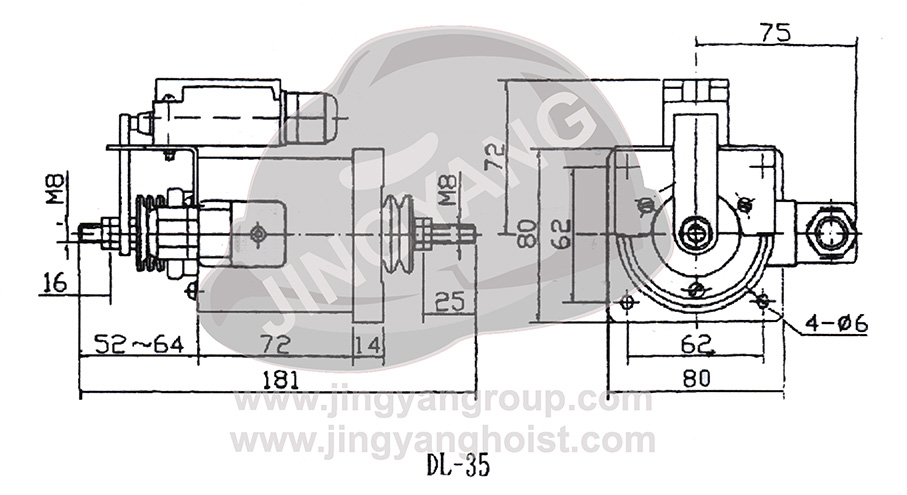

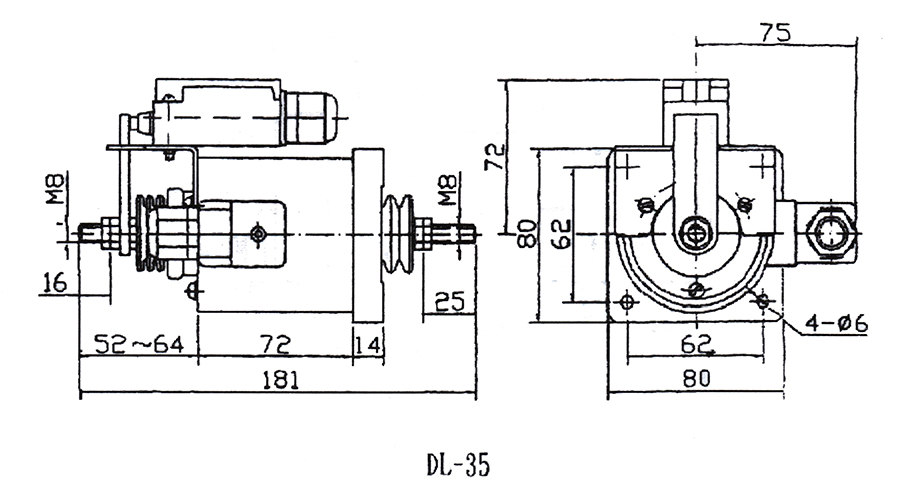

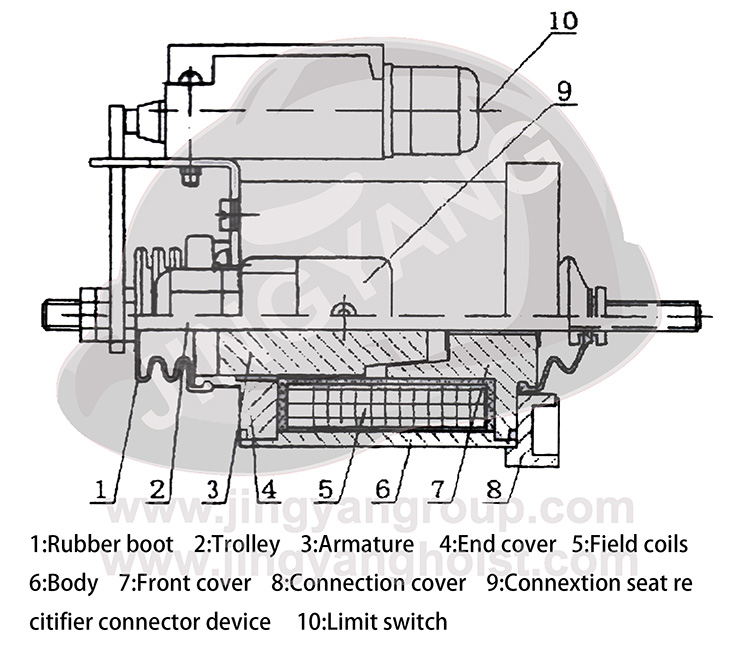

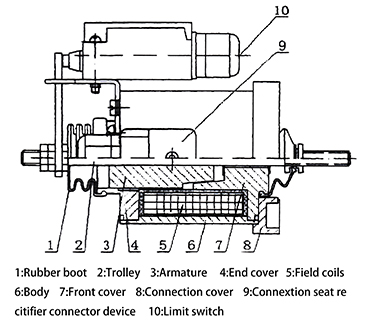

Factory supplied Spur Gear Rack And Pinion Cnc - DL-35 unilateral electromagnetic control – Jinyang Detail:

Relative spare parts:

| Item | Part No. | English name | Item | Part No. | English name |

| 1 | DL-0 | Cage | 31 | WG-19 | Worm gear fan |

| 2 | WG-0 | Reducing device | 32 | MAC-8 | Rubber |

| 3 | MAC-010 | Motor | 33 | WG-5 | Woem wheel |

| 4 | ZJ-0 | Mast section | 34 | WG-15 | Worm |

| 5 | XS-00 | Safety device | 35 | MAC-9 | Couping |

| 6 | HY | Hydraulic spring | 36 | MAC-020 | Pinion |

| 7 | TIE | Tie-in | 37 | ZJ100-10 | Rack |

| 8 | TL-2 | Safety device spanner | 38 | XK | Drop test operate box |

| 9 | PJ | Pipe joint | 39 | CT | Out operate box |

| 10 | BL100-G | Roller | 40 | FR | Resistance |

| 11 | BH-10 | Cable joint | 41 | PS | Waterproof plug |

| 12 | ML100-9 | Gate roller lower | 42 | SE | 3-phase swotch |

| 13 | ML100-10 | Gate roller upper | 43 | TC | Transfprmer |

| 14 | WM130-40 | Rope pulley | 44 | SDD | Annunciator |

| 15 | BS-10 | “J ” type screw | 45 | PLC | PLC Module |

| 16 | BQ-10 | Cable joint | 46 | QF | Creepage switch |

| 17 | BM-24 | Screw | 47 | SL | Limit switch |

| 18 | TL-1 | Roller spanner | 48 | FM | Belling |

| 19 | RA-9 | Adjustment unit | 49 | JS | Jacket |

| 20 | RA-12 | Brake pad | 50 | FS | Fan |

| 21 | SP | Spring | 51 | SY | EL lock |

| 22 | DL-110 | Rubber pad | 52 | F | Drop test plug |

| 23 | WG-03 | Brearing | 53 | KCE | Thermal relay |

| 24 | WG-030 | Oil seal | 54 | SQ | Braker |

| 25 | DXI-5 | Nylon wheel | 55 | KMB | Contactor |

| 26 | RA-13 | Rotary disk | 56 | BR | Brake unit |

| 27 | RA-120 | Brake piece | 57 | SPL | Speed relay |

| 28 | RA-10 | Brake disc | 58 | EL | Lamp |

| 29 | RA-7 | Electromagnet | 59 | CS | Calling system |

| 30 | CAM-3 | Counter roller | 60 | OL | Overload |

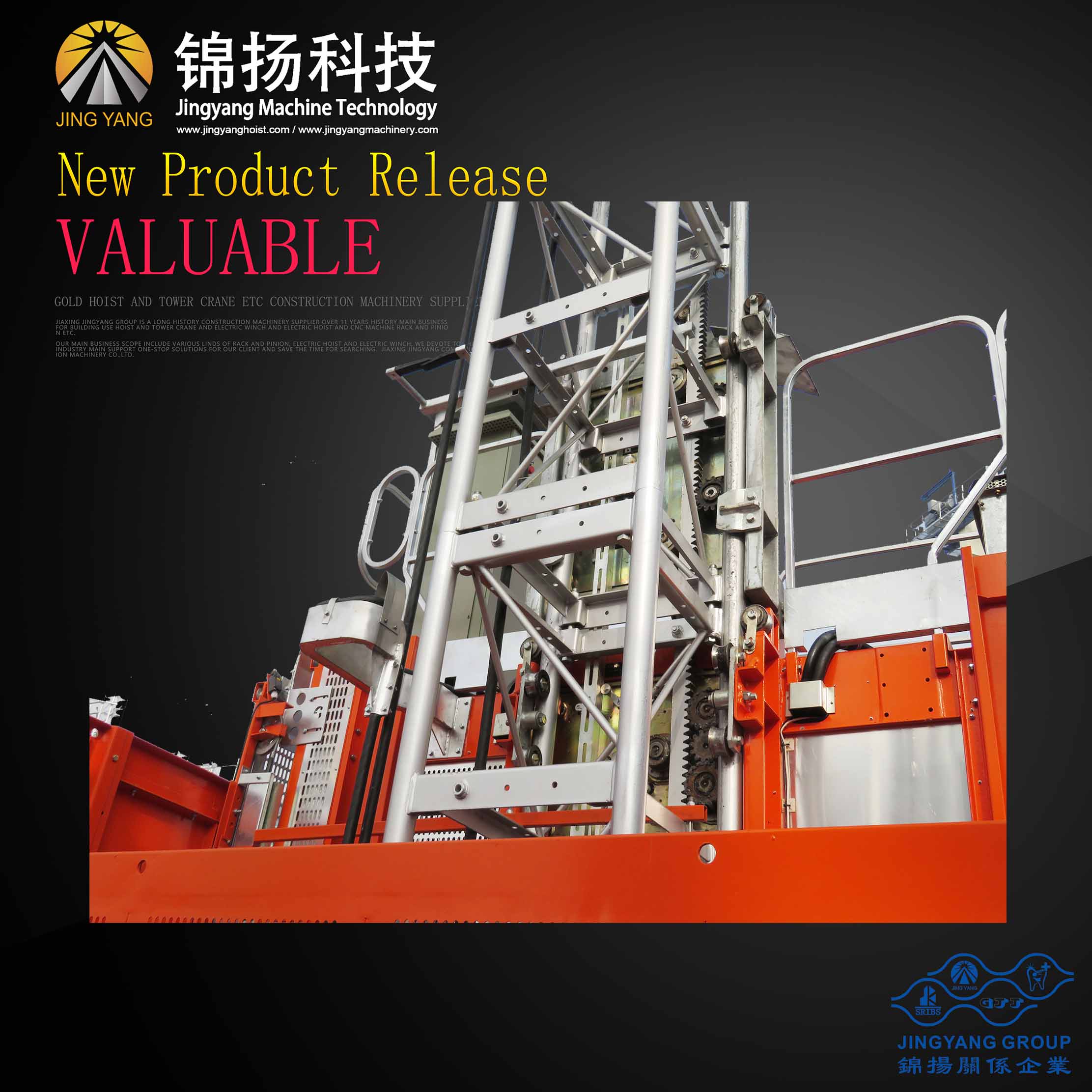

Product detail pictures:

Related Product Guide:

Motovario Geared Motors and Gearboxes from FCR Motion Technology | Gear Rack And Pinion

Head to Head Contrast: Columbus McKinnon (CMCO) & Lonking (OTCMKTS:LONKF) | Construction Hoist Parts

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Factory supplied Spur Gear Rack And Pinion Cnc - DL-35 unilateral electromagnetic control – Jinyang, The product will supply to all over the world, such as: Netherlands , Doha , Moldova , We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

We guaranee our product all origional GJJ high quality item, no fake item supply.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

-

2017 New Style Cnc Wood Craft Machines - CNC s...

-

OEM Manufacturer Harvester Combine Slewing Ring...

-

OEM Customized High Quality Vm2.5 R425 Long Blo...

-

Trending Products Construction Materials Lifter...

-

China wholesale Crane Load Moment Indicator - ...

-

Good User Reputation for Stainless Steel Propel...